The Role of CNC Machining in High-Performance Industries

In today's technologically advanced world, CNC machining plays a pivotal role across various high-performance industries. This technology has revolutionized the way we produce intricate components, offering unmatched precision and efficiency. From aerospace to electronics manufacturing, CNC machining metal parts have become indispensable. This blog will explore how CNC machining supports different sectors, highlighting its importance and applications.

Table of contents:

How CNC Machining Supports the Aerospace Industry

The Use of CNC Machined Metal Parts in the Automotive Sector

Why CNC Machining is Critical for the Medical Device Industry

The Importance of Precision CNC Metal Parts in Electronics Manufacturing

How CNC Machining Supports the Aerospace Industry

The aerospace industry demands precision, reliability, and high-quality components to ensure the safety and performance of aircraft. CNC machining is instrumental in producing complex parts with tight tolerances, which are crucial in aerospace applications. Components such as turbine blades, engine parts, and structural elements benefit from the precision and repeatability of CNC machining. By utilizing advanced materials and machining techniques, manufacturers can meet the stringent requirements of the aerospace sector.

The Use of CNC Machined Metal Parts in the Automotive Sector

The automotive industry relies heavily on CNC machining to produce various metal parts that contribute to vehicle performance and safety. CNC machining metal parts such as engine blocks, transmission components, and suspension parts ensures consistent quality and precision. Additionally, CNC machining allows for the production of lightweight yet strong components, contributing to fuel efficiency and overall vehicle performance. The ability to manufacture complex geometries with high accuracy makes CNC machining a preferred choice in automotive manufacturing.

Why CNC Machining is Critical for the Medical Device Industry

In the medical device industry, precision and quality are paramount. CNC machining enables the production of intricate components used in medical devices such as prosthetics, implants, and surgical instruments. The accuracy and repeatability of CNC machining ensure that medical devices meet stringent regulatory standards. Furthermore, the ability to work with biocompatible materials and produce highly customized parts makes CNC machining essential in developing innovative medical solutions that improve patient outcomes.

The Importance of Precision CNC Metal Parts in Electronics Manufacturing

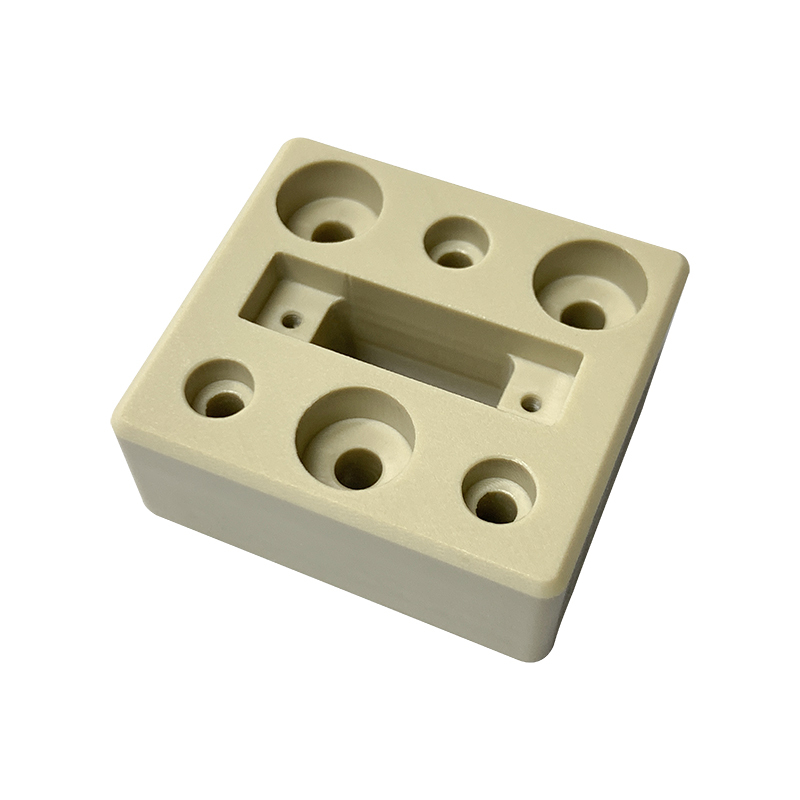

Electronics manufacturing requires components with extremely tight tolerances and high precision. CNC machining plays a crucial role in producing metal parts used in electronic devices, from connectors to housings and heat sinks. The capability to machine small, intricate features with high accuracy ensures reliable performance in electronic products. Additionally, CNC machining allows for rapid prototyping and iterative design processes, which are vital in the fast-paced electronics industry.

CNC machining has become a cornerstone in high-performance industries, offering unparalleled precision, efficiency, and versatility. From the aerospace and automotive sectors to medical devices and electronics manufacturing, CNC metal parts provide the quality and reliability demanded by these fields. By leveraging advanced materials and machining technologies, manufacturers can meet the stringent requirements and drive innovation in their respective industries. To explore more about CNC machining and its applications, visit our website.

Comments

Post a Comment