Enhancing Precision with Advanced Collimator Sights

Table of contents:

The Role of Collimator Sights in Modern Firearms

Benefits of Using Collimator Sights for Target Acquisition

Integrating Collimator Sights with Other Optical Devices

Maintenance Tips for Ensuring Optimal Performance

The Role of Collimator Sights in Modern Firearms

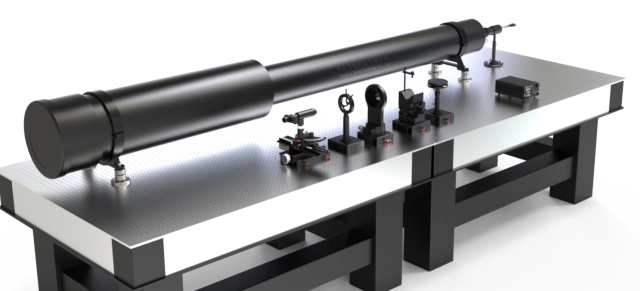

Collimator sights, such as the precision-engineered F-3000 Collimator, play an essential role in aligning beams and ensuring accurate targeting. Developed to produce parallel beams, they are a fundamental component in tools such as optical mounts, lasers, and imaging equipment. Used extensively in firearms, collimator sights allow for rapid and precise target acquisition by aligning the shooter’s line of sight perfectly with the reticle and the target. This enhances consistency and accuracy in various applications, whether in sports shooting, hunting, or military operations. The technology behind collimators relies on aligning a reticle or reference target plane with a parallel light beam, ensuring precision over varying distances. Devices that use collimator sights, like parallel hole collimators and converging collimator, provide multi-industry benefits, including optical calibration and testing, industrial imaging, and scientific research.

Benefits of Using Collimator Sights for Target Acquisition

The primary advantage of collimator sights is their ability to simplify and optimize targeting. By projecting a reticle onto the shooter’s field of view, collimators eliminate the need to align front and rear sights manually. This allows for faster target acquisition, a critical advantage in situations where time is of the essence. The F-3000 Collimator, for example, creates precision-aligned parallel light beams that enhance imaging accuracy and reduce distortion. Furthermore, its customizability allows integration with various optical accessories, optimizing use across different functions. Low scatter technology used in collimator designs minimizes distortion, ensuring superior image clarity and maintaining focus on the target, even under challenging conditions. Across industries, such innovations also prove beneficial in medical imaging, where precise beam control enhances diagnosis, and in industrial non-destructive testing (NDT), offering effective inspection solutions.

Integrating Collimator Sights with Other Optical Devices

Collimator sights truly shine when paired with complementary tools. For instance, pairing collimators with front mirrors or observation microscopes significantly expands their range of applications. By using converging collimators alongside star pattern plates and viewing microscopes, scientists and technicians can evaluate lenses, mirrors, and prisms for clarity, quality, and performance. Similarly, optical devices matched with collimators optimize applications such as lens quality testing, focal length measurement, and long-distance targeting. The F-3000 Collimator exemplifies compatibility, seamlessly integrating with a suite of complementary devices to improve diagnostic and operational capabilities. Furthermore, collimators such as the F-3000 are built to accommodate OEM custom solutions, offering tailored benefits across diverse industry applications from precision alignment in research to flawless beam control in manufacturing.

Maintenance Tips for Ensuring Optimal Performance

Like any advanced device, maintaining your collimator sight is vital to ensure long-lasting performance. Start by cleaning the optical lens regularly with appropriate solutions to prevent dust or smudges from affecting performance. Inspect mounting hardware for integrity and adjust alignment when necessary to maintain accuracy. Devices like the F-3000 Collimator often come equipped with fine-tuning brackets, enabling precise adjustments as required. For electronic components, such as those integrated with stabilizing power supplies in advanced collimators, ensure the power supply settings are compatible and avoid overloading to extend the device’s operational life. When storing the device, ensure it’s kept in a clean, stable environment away from excessive moisture or extreme temperatures to protect its components. Finally, routine inspections by technical professionals are recommended to prevent equipment degradation, ensuring the collimator remains a reliable asset across its lifespan.

From enhancing shooting accuracy to optimizing industrial and medical imaging, collimator sights are becoming indispensable in achieving precision and efficiency. Their ability to project parallel beams or precisely aligned optics makes them valuable tools across multiple industries, including military, healthcare, manufacturing, and scientific research. Whether it’s the pioneering advantages of parallel hole collimators or the innovative design of solutions like the F-3000 Collimator, collimator sights represent a leap forward in technological progress. By understanding their role and maintaining them effectively, users can unlock their full potential and enjoy unparalleled precision.

Comments

Post a Comment